The Grape Crusher-Destemmer, Destemmer-Only, or Destemmer-Crusher are the necessary part of winemaker equipment. That machine divides the grapes from the stems and crushes the grape. The result is sugary juice that is going to be fermented. But how to choose the right grape Crusher Destemmer?

I’m using this old type of grape crusher-de-stemmer. It serves its purpose now, but apparently, I have to buy something newest. I need to buy something more efficient also. My production quantities exceed the capacity of the existing machine. So let’s do the research.

Three Different Functional Areas

Three different functional areas are the main characteristic of this machine in general. The reception hopper is the first one. There you can dump the grapes. From here, they are served to the following section of the device. The following two areas can be in either order. In some cases, the next two fields are not even present. The rollers are performing the crushing function in the second area. Many different materials, configurations, and sizes can be connected to the rollers. The third is the Destemming area, which is frequently referred to as the Destemming Cage or Destemming Basket. The Destemming area comprises a stainless steel drum/basket perforated. Inside this drum, a rod with paddles is called the beater or destemming shaft, rotating. This bar’s spinning forces the grapes toward the stainless drum, where the perforations split the grapes from the stems.

Let’s talk about three configurations for the devices; their primary purpose is more or less apparent from the name.

Grape Crusher Destemmer:

These cheaper devices are suitable primarily for home winemaking purposes. As you can see from the title, “Grape Crusher Destemmer” first crush the entire cluster of grapes and only then separate the stems from the fruit. This device is much cheaper to produce, but you have to know that what is cheaper is not always better. This type of machine has the shortcoming of moving the stems throughout the crushing rollers before the destemming process. This disadvantage can cause some extraction of unwanted characteristics from the stems. This disadvantage also causes less effectiveness at separating all the grapes’ stem content. This can cause too many stems to appear in the fermenter. The price range is between $350 and $1200.

Destemmer-Only:

The price of this type is between grape Crusher Destemmer and Destemmer-Crusher devices. These machines are without rollers. These devices have a very rough destemming maneuver. This action tends to crack open the grapes even if they don’t have rollers. In this process, grapes aren’t wholly crushed before destemming happens. Thus, destemming is more efficient and allows more quality of the must, in any case, better than the Crushing-Destemming unit. Additionally, you have to know that these machines have integrated must pumps. In fact, this means that they have a paddle wheel in the housing. What is essential is that after that treatment, the must will be without whole grapes, which can produce unwanted flavoring in the future wine. In any case, this is an excellent alternative for a little winery that is looking for more outstanding quality wine and which cannot afford the higher cost of a proper Destemmer-Crusher. Prices range from about $2500.

Destemmer-Crusher:

Pay attention; this isn’t grape Crusher Destemmer but Destemmer Crusher. When you have more commercial needs, this type of machine is the best option. We can say that, in this case, Destemmer-Crusher is an expensive choice. Much more expensive than Grape Crusher Destemmer. But this is the best choice for larger producers. The most significant benefit of this system is that the stems are kept intact after the grapes are separated from the stems. This mode allows that destemming to be more efficient because it prevents the steams from being passed through the rollers. The result is a better must. And, of course, better must mean better wine. The grapes are also handled more gently in the process. Gentle handling of grapes causes less injury and extricates less tannin through processing. This process’s added value (destemming first) is also a sorting table. This sorting table allows the grapes to be sorted on a sorting table. This means that we can remove any final stems, leaves, bugs, or other impurities. The price is, of course, very high. Start at about $8500.

What to Choose?

The choice between these models can be tricky. Is grape Crusher Destemmer good enough? Maybe if you haven’t too many grapes for processing. The choice depends on how many grapes you are growing or working with. This part is the leading guide to choosing the right type of crushing/destemming machine. The total amount of grapes in the year isn’t the most important. The most important is the biggest single lot of grapes. Your decision must be based on this fact. Doing all the work in 4-5 hours could be your guide. Don’t forget that you have to clean your machine after every use. This cleaning process could demand the rest of an 8-10 hour work. This calculation does not apply to the hand-cranked models. It’s almost impossible to insist on tireless manual work longer than one hour. After all, you’re just a man.

Choose Something Among the Next Models

You can read the breakdown of how much fruit the machines can process in an hour on the link below. This information can help you decide. And remember. Quality is also important. Maybe even more than quantity. So, If your wine production is large enough, the following grape Crusher Destemmer could also serve you well. Click on the picture to read more about its properties.

My friend has a small winery in South America, and he asked me to see a machine or tool to help him with the process; crush the fruit, and or strain the grapes seeds off?

Hi,

Thank you for such an interesting question that prompted me to write a new article on the subject in the coming days. Here are so many questions and answers regarding this issue that is impossible to answer in short. What is small for you? What are the goals of your friend? What type of wine does he wish to produce? All this and much more.

The main goal is that you have to do this process as quick as possible to prevent the activity of harmful bacteria already at the beginning.

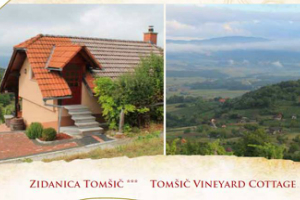

But let me try to answer it briefly. I consider myself to be a hobby vinegrower. I process about 1000 vines. And I’m totally fine with my old red grape crusher destemmer you can see in the picture and with my grape press machine which you can find it on this article. https://ourvineyardcottage.com/grape-press-machine

Regards

Jože